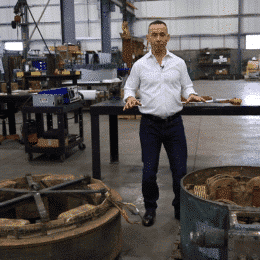

Notable Project: Gerdau Long Steel – St. Paul DC reactor coils

Gerdau Long Steel - St. Paul, MN

Problem: Our customer’s existing DC reactor coils were beginning to leak coolant, and the OEM, General Electric, no longer supported the equipment. Gerdau Long Steel could not continue to operate their DC electric arc furnace with their existing coils, and were having difficulty solving their problem.

Solution: The project began as a repair of an existing coil, but subsequently transformed into the manufacture of two (2) new DC Reactor coils. We developed a process to wind new coils on our horizontal table and join the tubing via the silver braze method. The unique heavy wall copper tubing was sourced from Europe.

Eager to solve problems, I2r POWER’s technical team is more than willing to help you unravel your challenges.

Have questions about this topic?

More Articles

Power Cable Donation to Kent State enhances student experience

Power Cable Donation to Kent State enhances student experience I2r POWER recently provided two new sets of water-cooled power cables to the foundry and metal casting facility at Kent State University’s College of Aeronautics and […]

Read MoreEnd-of-Year Holidays Time to Express Gratitude

End-of-Year Holidays Time to Express Gratitude It’s time to celebrate a successful, though at times difficult, year! We made it! The company holiday party is an ideal time to share our gratitude for all those […]

Read MoreElectromagnetic caster stirrer designs vary depending on use

Electromagnetic caster stirrer designs vary depending on use Electromagnetic stirrers for steel applications produce very low frequency, high amplitude magnetic fields to agitate steel when molten. Steel applications include ladle stirring and stirring in continuous […]

Read More