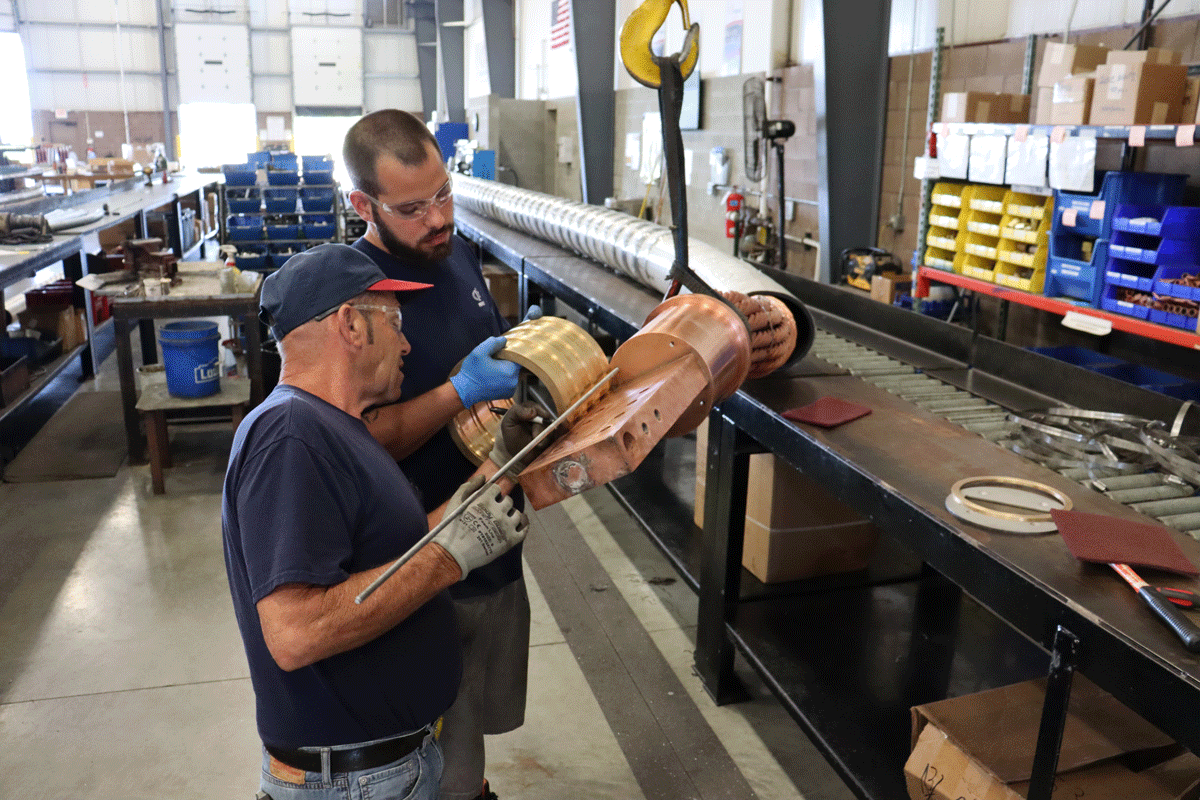

Notable Project: Enormous CMC Steel-Sayreville EAF power cable

CMC Steel – Sayreville, NJ Massive Rotating Terminal Design

Problem: The customer needed to enhance the longevity of their EAF power cable and mitigate hose binding during operation.

Solution: In what might be the largest EAF rotating terminal assembly built in North America, our engineers custom designed a 14,000 MCM terminal assembly measuring 27.25” with a 10” diameter and a 17” exposed blade. The designed called for 66 lbs. of silver solder applied to the 208-pound terminal weighing in at an approximate total of 275 lbs. The entire cable weighs more than 3000 lbs.

Eager to solve problems, I2r POWER’s technical team is more than willing to help you unravel your challenges.

Have questions about this topic?

More Articles

Power Cable Donation to Kent State enhances student experience

Power Cable Donation to Kent State enhances student experience I2r POWER recently provided two new sets of water-cooled power cables to the foundry and metal casting facility at Kent State University’s College of Aeronautics and […]

Read MoreEnd-of-Year Holidays Time to Express Gratitude

End-of-Year Holidays Time to Express Gratitude It’s time to celebrate a successful, though at times difficult, year! We made it! The company holiday party is an ideal time to share our gratitude for all those […]

Read MoreElectromagnetic caster stirrer designs vary depending on use

Electromagnetic caster stirrer designs vary depending on use Electromagnetic stirrers for steel applications produce very low frequency, high amplitude magnetic fields to agitate steel when molten. Steel applications include ladle stirring and stirring in continuous […]

Read More